What is CNC Macro Simulator II

CNC Macro Simulator II is a professional-grade CNC simulator widely recognized and trusted across the

manufacturing

industry. Designed for both experienced CNC programmers and beginners, it provides a safe, controlled

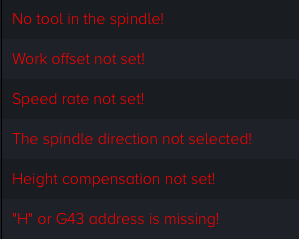

environment for learning, developing, testing, and debugging advanced CNC macro and parametric programs

without risking machine downtime.

Supporting Fanuc, Haas, Mazak ISO, and Centroid controls, CNC Macro Simulator II is purpose-built for heavy, complex macro programming and sophisticated parametric logic. Industry professionals rely on it to validate high-level CNC programs before deployment on real machines, while beginners use it to build confidence, understand macro behavior step by step, and gain practical CNC programming skills.

By combining industry-proven accuracy, real-world control compatibility, and beginner-friendly learning capabilities, CNC Macro Simulator II serves as an essential CNC simulation tool for machine shops, manufacturers, training centers, and automation specialists seeking reliable CNC macro development and validation.

Supporting Fanuc, Haas, Mazak ISO, and Centroid controls, CNC Macro Simulator II is purpose-built for heavy, complex macro programming and sophisticated parametric logic. Industry professionals rely on it to validate high-level CNC programs before deployment on real machines, while beginners use it to build confidence, understand macro behavior step by step, and gain practical CNC programming skills.

By combining industry-proven accuracy, real-world control compatibility, and beginner-friendly learning capabilities, CNC Macro Simulator II serves as an essential CNC simulation tool for machine shops, manufacturers, training centers, and automation specialists seeking reliable CNC macro development and validation.

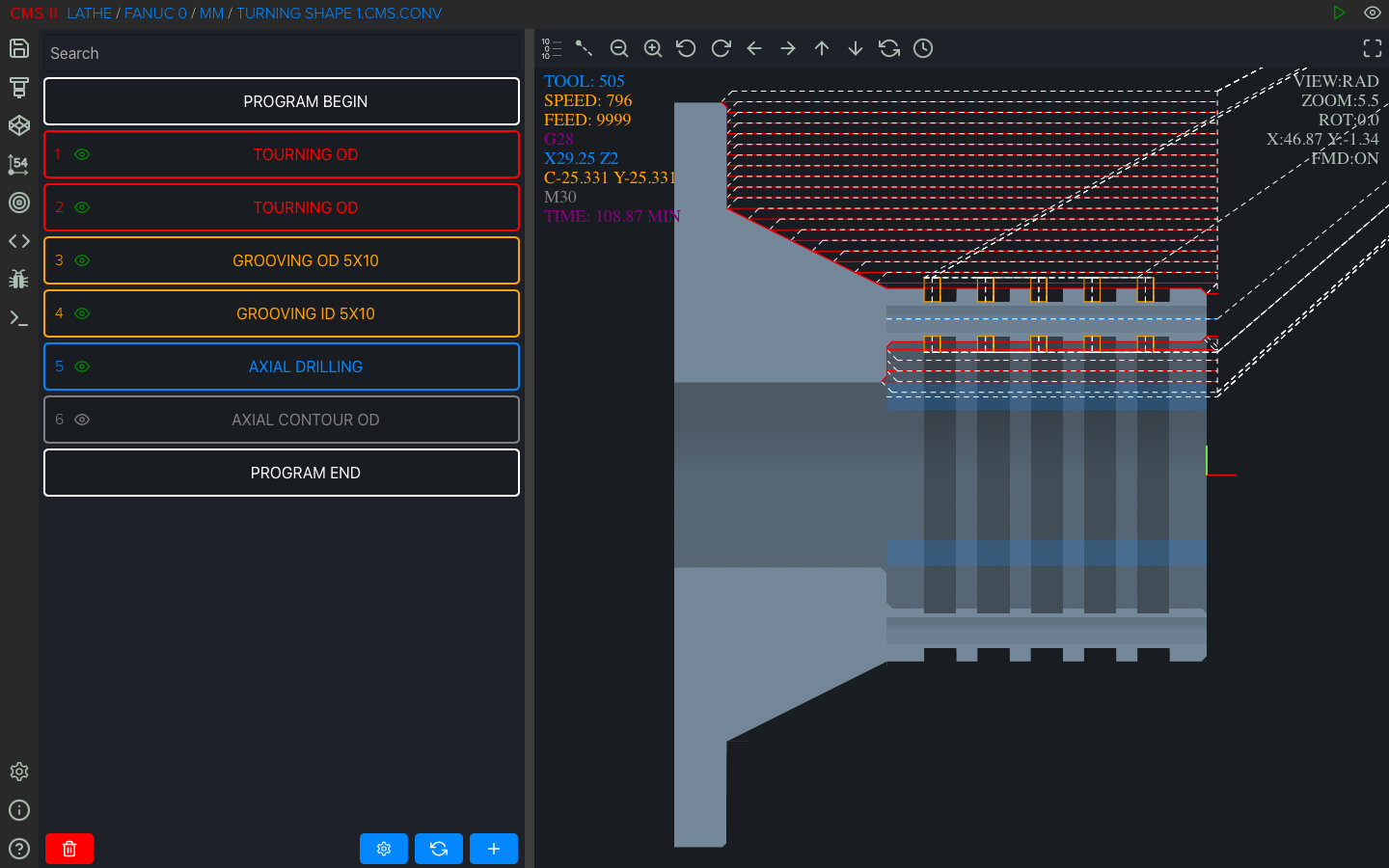

- program and simulate 3-axis mills and lathes, including machines with C/Y axes and live tooling, using advanced macro functions,conversational programming, and intelligent autocomplete

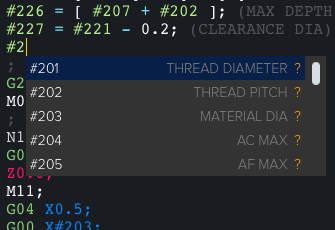

- advanced autocomplete system (available in desktop mode only) enabling quick access to common variables, templates, custom templates, user-defined variables, Macro Fanuc B/Centroid reserved words, and Micro Commands

- supports 3-axis milling machines and lathes with C & Y axis + live tooling

- advanced macro support such as: SETVN, DPRNT and G-code and M-code custom macro call

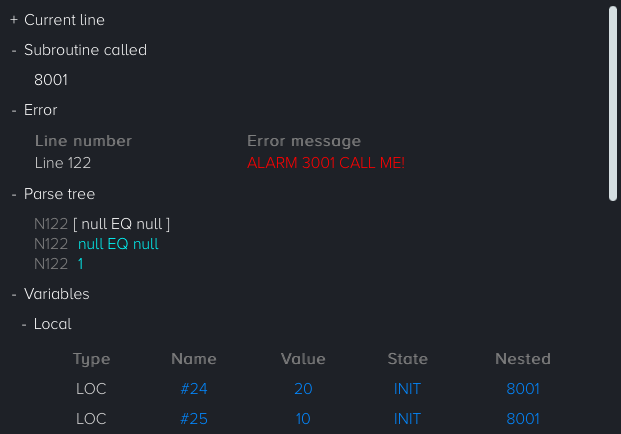

- a powerful debugging tool: Step forward or backward through CNC macros with real-time variable editing

- one-time purchase with no time limits, no subscriptions, no accounts, and no device number restrictions

- frequent free updates and feature upgrades

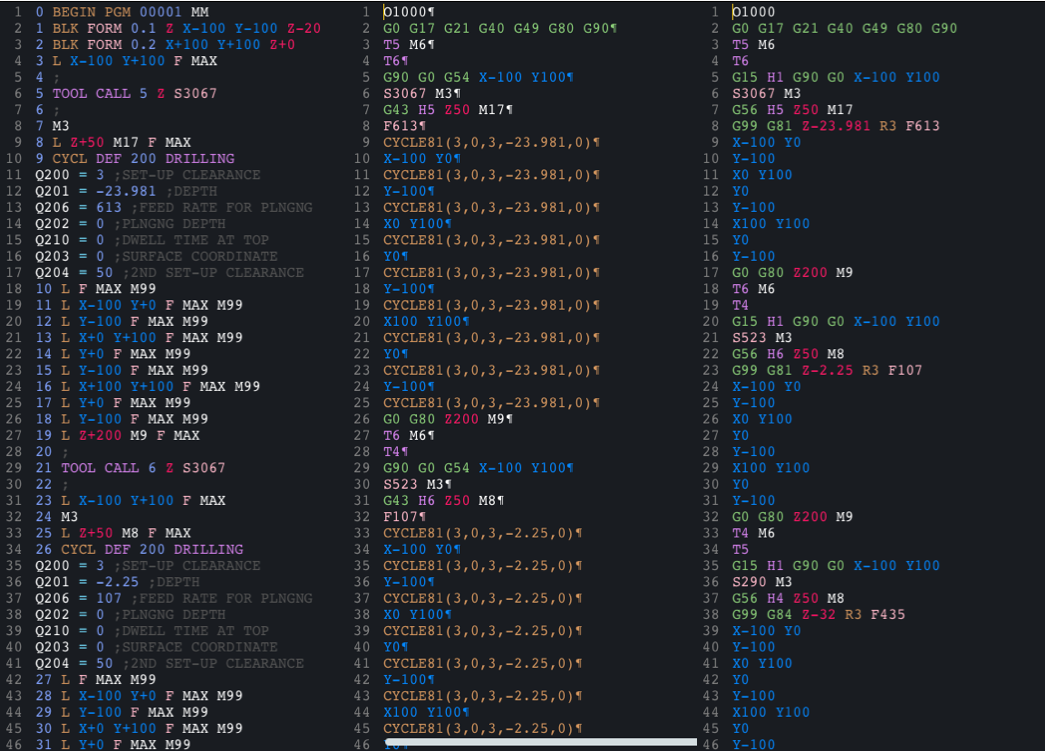

- export macro/ISO programs to plain ISO, Sinumerik, Heidenhain, and Okuma Learn more

- Direct Drawing Dimension Programming (chamfering and rounding) in the lathe mode

- macro support for Fanuc, Haas, Yasnac, Mitsubishi, Centroid, Mazak ISO or Sinumerik 802D

- powerful and straightforward conversational mode (with the ability to add your own cycles) for 3-axis milling machines and lathes with C axis + live tooling

- works offline, does not require internet connection

- runs on Windows, Linux, MacOS, Android and IOS

- can be used on desktop, tablet or even mobile phone